Drive & Controls

Thanks to a frequency converter speed and direction of rotation of the cleaning rollers can be steplessly controlled. Of course the trimming machine also has safety switches and emergency stop.

Table

For feeding the brushes, there is a height-adjustable table on the input side of the machine, which makes it easier for the operator to insert the products always at the exact height. Depending on customer requirements, a folding table or a ejection slide can be installed on the output side of the machine.

Height Adjustment

The distance of the conveyor belts to the cleaning rollers can be adjusted quickly and easily mechanically. The belts are specially coated and seamlessly glued to ensure optimum transport. The filled material of the rollers is chosen so that the bristles of your products are not damaged during the cleaning out but with the highest possible degree of cleaning.

Lateral Adjustment

Also the distance of the conveyor belts is mechanically adjustable via two hand cranks. Thus, brushes of the smallest size can be processed just as reliably as large ceiling brushes.

Machine Frame

Everything on board - the solid welded steel frame hides drives and control cabinets. Powder-coated cover panels and the complete housing protect the environment from dirt and ensure a clean look. Enclosures at safety-relevant points are secured with limit switches. Inside is a collecting box for the cleaned-out particles which are discharged by a suction.

Dust Exhaustion

Loose filaments and sections are sucked off inside the machine. For this purpose, at the critical points sufficiently large openings are present, the tubes are merged on the back of the machine for connection to an external stationary or central exhaust. In addition, the housing protects against excessive dust and noise in operator's working area.

We optionally supply a mobile dust extraction system that ensures clean operation of the system if there is no central exhaustion system. In addition, the exhaustion device can be equipped with a mobile soundproof housing.

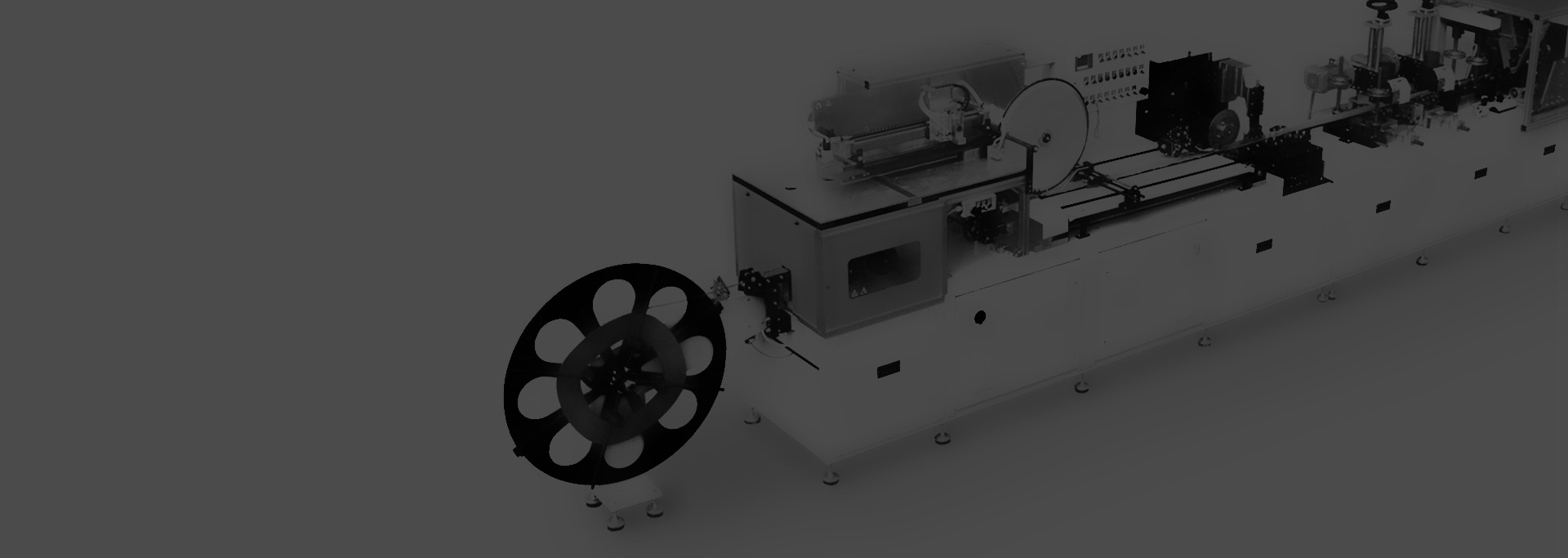

Cleaning Machine

- easy and safe operation

- solid construction

- reliable and durable

- low wear

- Brush width. Maximum 150 mm.

- Speed. Variable up to 6 meters per minute.

- Rollers. Filled material PP 2.0 mm white. Others on request.

Request regarding Cleaning Machine:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com