Clamping Stations

The brooms are inserted by the operator into the automatically opening clamping holder. The base plates of the clamping fixtures offer flexible adaptation options to a wide variety of brush sizes. Products up to 80 centimeters long can be processed on this machine, up to 1 meter for an additional charge. For smaller items, it is also possible to clamp two brushes per holder to increase capacity.

Devices

Inside the machine, in addition to two rotating shearing units, there are three cleaning rollers and, depending on the requirements, flagging and beating devices. The installation of clipper blades is also possible.

Ejection

The finished broom is separated from the tensioning station by an automatic ejection. The product can also be removed manually.

Drive & Controls

A powerful geared motor feeds the conveyor chain, its speed is infinitely variable via a potentiometer, as is the beating unit for pushing open the flagged filaments. Each unit can be switched on individually. In order to achieve the perfect trimming result, various program sequences can be set, such as driving the units over once, twice or even three times.

With the lowest possible electronic effort, we achieve maximum ease of use. Simple operation, longer life and low susceptibility to failure are the advantages of this control concept.

Dust Exhaustion

Loose filaments and sections are sucked off inside the machine. For this purpose, at the critical points sufficiently large openings are present, the tubes are merged on the back of the machine for connection to an external stationary or central exhaust. In addition, the housing protects against excessive dust and noise in operator's working area.

We optionally supply a mobile dust extraction system that ensures clean operation of the system if there is no central exhaustion system. In addition, the exhaustion device can be equipped with a mobile soundproof housing.

Machine Frame

Everything on board - the solid welded steel frame hides drives and control cabinets. Powder-coated cover panels protect the interior from dirt and ensure a clean look. Enclosures at safety-relevant points are secured with limit switches.

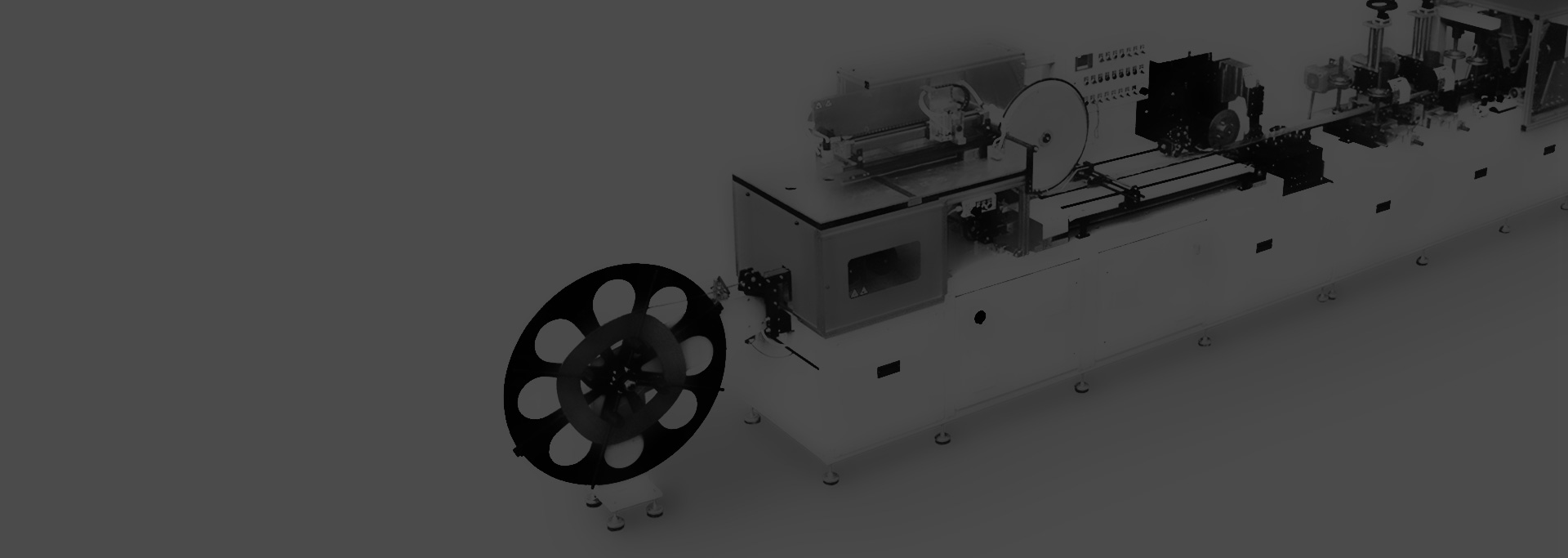

Continuous Trimming Machine

The WOMAtec "TRIM 2.0 auto" continuous trimming machine is the perfect addendum to your brush drilling and filling machine. From design to programming to production, WOMAtec realizes everything in-house. Thanks to the sophisticated machine concept and the solid and high-quality construction, you get a machine that is characterized by:

- an excellent milling image

- easy operation and maintenance

- reliability and longevity

- high productivity and flexibility

- low noise and dust emission

- high proportion of standard parts and thus

- easy access to wear and spare parts

- Brush/Broom. Maximum 800 x 150 mm.

- Capacity. Maximum 6 meters per minute - depending on the size and material of the workpiece.

- Clamps. 6 mechanical clamping stations.

- PDF file

Request regarding Trimming Machines:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com