Brush Clamping

The cylinder brushes are inserted by the operator into the head stock by hand or lifter. The tailstock is clamping the brush pneumatically.

Devices

The trimming device is equipped with an attachment bracket for quick exchange of cutting tools. Not only synthetic of natural fibers can be cut but also abrasive or all kind of wire filaments. The depth is adjusted mechanically using a hand wheel, as is the case with the cleaning unit.

Using a template, the brush can be designed conically or with an individual cutting contour.

Machine Frame

Everything on board - the solid welded steel frame hides drives, control cabinets and material collection box. Powder-coated cover panels protect the interior from dirt and ensure a clean look. Enclosures at safety-relevant points are secured with limit switches.

Drive & Controls

A powerful geared motor feeds the main spindle, its speed is infinitely variable via a potentiometer, as is the trimming unit and feed rate. Each unit can be switched on individually. In order to achieve the perfect trimming result, various program sequences can be set, such as running the units once, twice or even three times.

With the lowest possible electronic effort, we achieve maximum ease of use. Simple operation, longer life and low susceptibility to failure are the advantages of this control concept.

Foot Switch

The pneumatic tailstock is actuated via the foot switch. After closing the sliding doors, the operator starts the machine via the control panel. Once the shearing process is complete, the doors can only be opened when all engines have stopped.

Chip Collection & Dust Exhaustion

Loose filaments and sections are sucked off inside the machine. For this purpose, at the critical points sufficiently large openings are present, the tubes are merged on the back of the machine for connection to an external stationary or central exhaust. Material that cannot be extracted falls down a chute into the collection container. This can be pulled out like a drawer and easily emptied. In addition, the housing protects against excessive dust and noise in operator's working area.

We optionally supply a mobile dust extraction system that ensures clean operation of the system if there is no central exhaustion system. In addition, the exhaustion device can be equipped with a mobile soundproof housing.

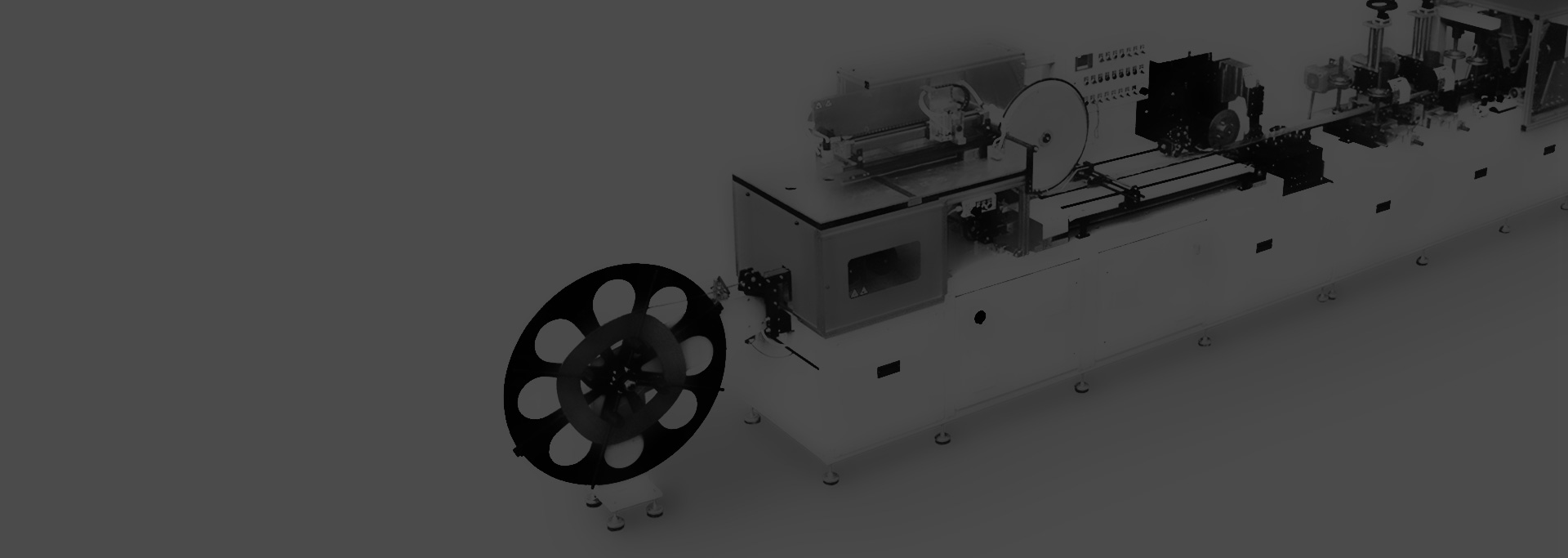

Cylinder Brush Trimming Machine

The WOMAtec "RBT 2.0" cylinder brush trimming machine is perfectly suitable for various sizes and materials. From design to programming to production, WOMAtec realizes everything in-house. Thanks to the sophisticated machine concept and the solid and high-quality construction, you get a machine that is characterized by:

- an excellent milling image

- easy operation and maintenance

- reliability and longevity

- high productivity and flexibility

- low noise and dust emission

- high proportion of standard parts and thus

- easy access to wear and spare parts

- Brush length. Maximum 900 mm - longer on request.

- Brush diameter. Maximum 500 mm - larger on request.

- Material. Synthetic, natural, abrasive, wire filaments.

- PDF file

Request regarding Cylinder Brush Trimming Machines:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com