Controls

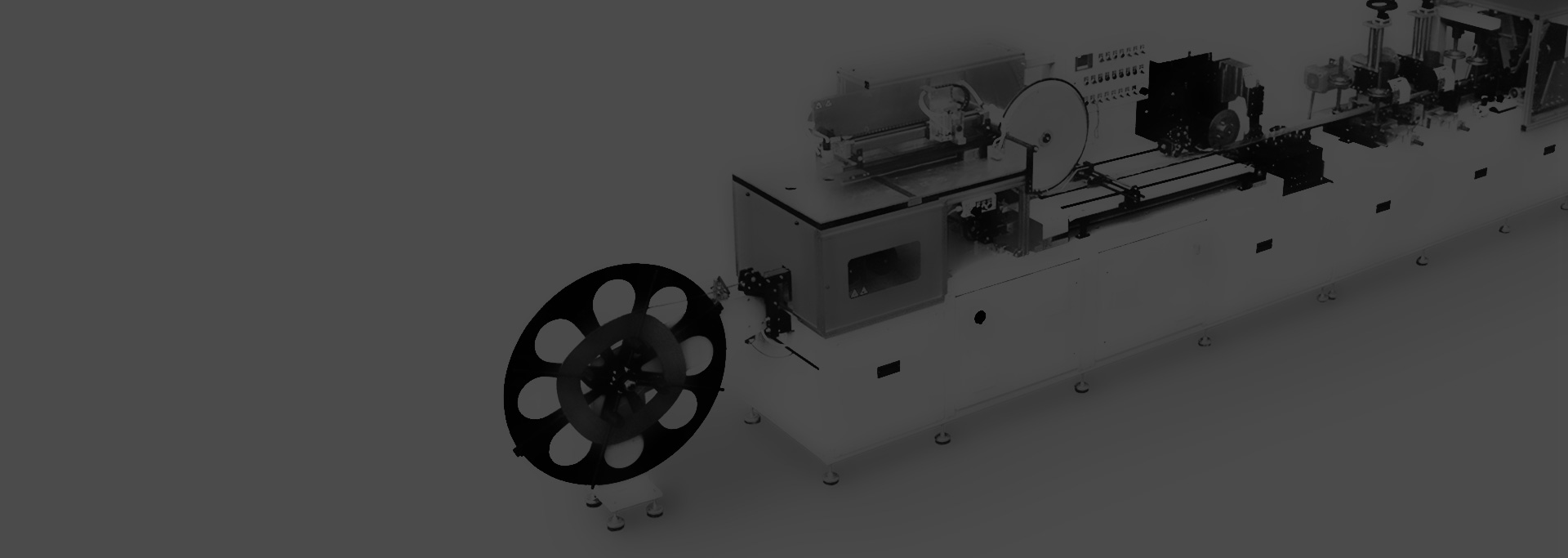

The high-quality 15-inch Beckhoff touch panel enables quick and easy operation of the WOMAtec CNC control. The user interface is clearly structured and includes all standard functions such as manual, automatic and programming mode, fault diagnosis, recipe management, etc. The remote control helps to program and set up the machine. The specially developed dxf-converter automatically calculates the travel paths of the milling cutters from a 2D contour drawing. The picture shows an automatic copying shaper Boucherie KBF completely overhauled and modified from template to CNC control system.

Mechanic

The CNC retrofit also includes the complete mechanical overhaul of the machine. It gets disassembled to the last screw, cleaned, reworked, replaced wearing parts. New milling motors, drive belts, guides, bearings ... This overhaul doubles the lifetime of the machine because it is like new again!

Machine Frame

The basic structure of the machine is retained, thus also the extremely stable frame, various castings and the well thought-out technology. Only the fragil hydraulic or pneumatic control and the old electrical system must give way to new technologies. But this as sustainable as possible - due to the high proportion of freely available standard parts, e.g. from FESTO or BECKHOFF you can rely on spare parts in the long term and carry out repairs yourself as far as possible.

Pneumatic

Workpiece clamping and hopper feeder assembly work with FESTO cylinders. On request, this can also be realized with electronic axes.

Safety

Housings, safety devices, limit switches and of course emergency stop are completely renewed and integrated in the new control system. Upon request, light bars, robotic equipment or other automated feeding and safety systems can also be integrated.

Exhaustion

Large openings at the critical points allow for the best possible removal of wooden chips. In addition, the enclosure protects against excessive dust and noise in operator's working area.

CNC Retrofit Automatic Copying Shaper

- three CNC-axis for contour shaping (cutter 1 and 2, rotating table)

- latest safety standard

- universally combinable with all popular machine brands and types

- including CE, manual and sparepart list

- retrofit available for customer machines or used machines from the WOMA portfolio

- Capacity. About 10 to 15 seconds per milling process - depending on the size and shape of the workpiece.

- Cutter motors. Each 5,5 kW.

- Cutter speed. Approx. 9.000 rotations per minute.

Request regarding CNC Retrofit Automatic Copying Shaper:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com