Controls

The high-quality 15-inch Beckhoff touch panel enables quick and easy operation of the WOMAtec CNC control. The user interface is clearly structured and includes all standard functions such as manual, automatic and programming mode, fault diagnosis, recipe management, etc. The remote control helps to program and set up the machine. All control components are from Beckhoff, whereby WOMAtec attaches great importance to long-term availability of the parts and to using only standard parts, which can be obtained from the international Beckhoff spare parts service. Upon request, robotic equipment or other automated feeding systems can also be integrated.

Safety

Housings, light bars, limit switches and of course emergency stop are completely renewed in accordance to the latest CE safety standards. Thanks to the modern drive technology and large connections for the suction, the operator is only exposed to extremely low dust and noise emissions.

Clamps

The clamps specially made for the brush model work precisely and hold the brush in position when drilling. They are operated with the foot switch. In manual mode, this can also be done by the touch display or the remote control. The CNC table can be supplied for flat brushes with 2 axes, for radial, roller or disc brushes with up to 4 axes.

Mechanic

The CNC retrofit also includes according to machine condition and customers requirements a partial or complete mechanical overhaul of the mechanic. The WOMAtec retrofit doubles the lifetime of the machine, saves money and resources!

Pneumatic

Tubes, cylinders and sensors are completely renewed. All pneumatic components are supplied by FESTO. The modern valve terminal is electronically connected to the CNC control. Of course new pneumatic and electrical circuit diagrams are created as well as the CE certificate.

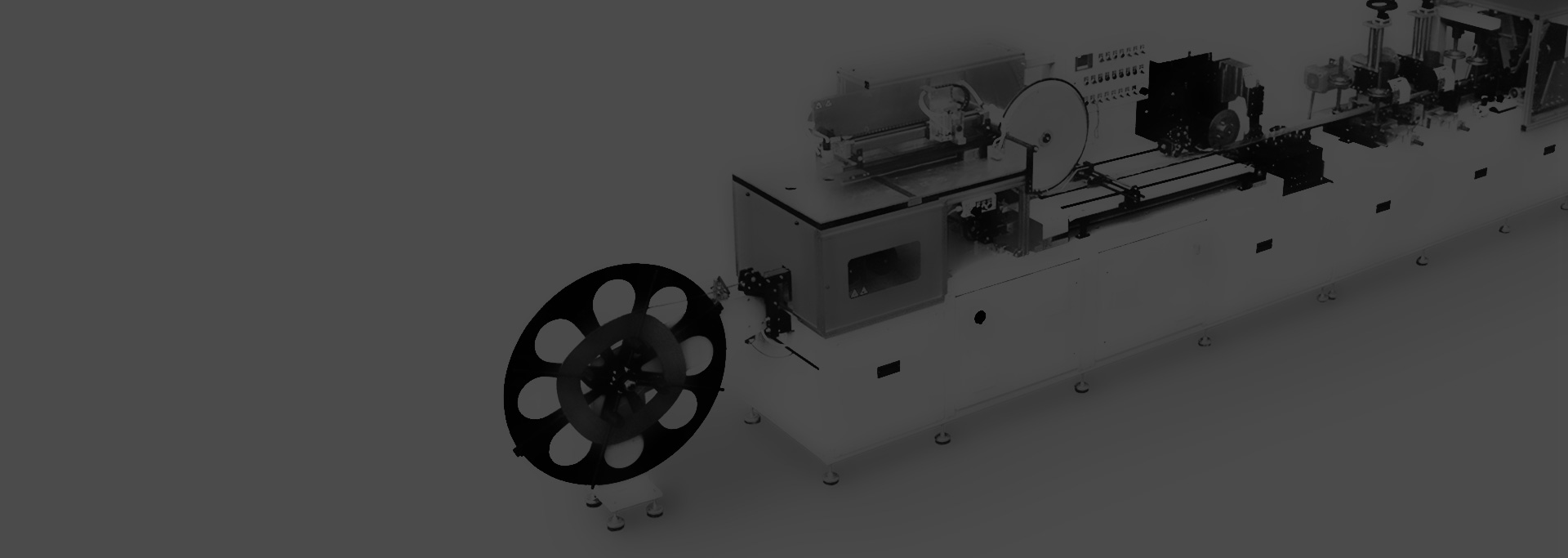

CNC Retrofit Brushmaking Machine

- new servo drives

- compact control cabinet

- Windows based brush software for up to 6 axis

- universally combinable with all popular machine brands and types

- Speed. Up to 600 tacts per minute.

- Elektronic. On Beckhoff basis.

- Pneumatic. Exclusively FESTO.

Request regarding CNC Retrofit Brushmaking Machine:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com