Chuck

The pneumatically controlled and specially for this application developed chuck has replaceable fingers made of hardened steel. It captures all brush sizes safely and scratch-free. The pulleys for the yarn guide are pneumatically controlled.

Drive

The special motor works quietly and reliably. It gets along without high voltage power supply and electronic control.

Pedals

The foot pedals are operating chuck and rotary motion of the brush. As with a sewing machine, the rotational movement can be controlled by pressure on the pedal.

Machine Frame

The solid welded steel frame ensures stability of the machine. The operator works comfortably in sitting position in front of the device.

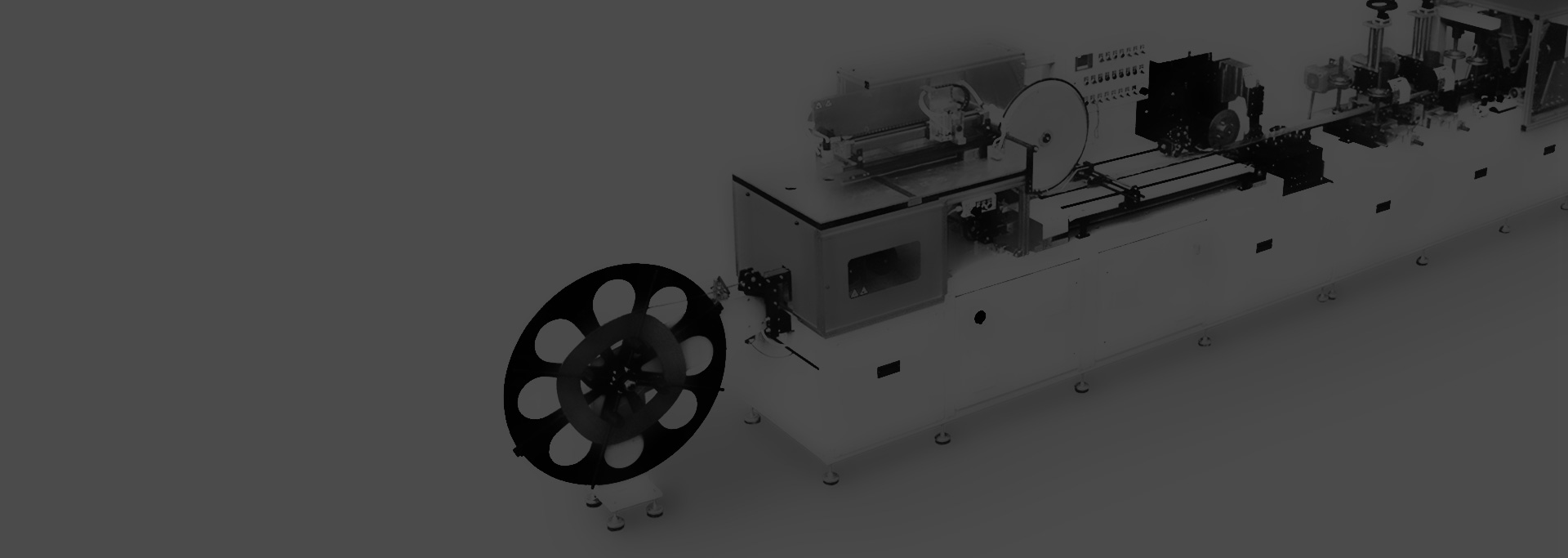

Paintbrush Bonding Machine

- proven technology

- solid construction

- reliable and durable

- universally applicable

- Handle Ø. From 0 to 30 mm.

- Supply. 0,37 kW / 230 V / 50 Hz.

- Capacity. Approx. 2 paintbrushes per minute.

Request regarding Bonding Machine:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com