Waterjet Cutting

WOMAtec not only uses this modern industrial manufacturing process for its own mechanical engineering, but also offers waterjet cutting as a contract manufacturer.

Water jet cutting is especially convincing due to the versatile application fields, the ease of use and the increase in efficiency. The technology of water jet cutting allows to cut almost any material. Therefore, we produce with our modern plant for customers in the fields of:

► Metal cutting, in particular aluminum

► Tool and mold making

► Automotive industry

► Stone and tile processing

► Glass processing

You only provide us with a CAD file of your production part (alternatively we can also create it). This is read into the machine, where the travel distances are calculated using the special software. Based on these calculations, you will receive our quotation. If you give us the order, the actual production begins after just a few machine settings. We are happy to provide you with the material and finishing as well.

Technology

3-axis high pressure water jet cutting system with a pure water or abrasive cutting head.

Travel speed: freely adjustable up to 10 meters per minute

Positioning accuracy: ± 0.1 mm

Repeatability: ± 0.1 mm (per meter at 20 °)

Z-axis clearance: 180 mm

Plate size: maximum 3,000 x 1,500 mm

Application areas

Cut to size for further processing

Prototypes

One-off and series production

Advantages

Increased efficiency through time savings, especially in metal cutting

High flexibility

High precision

Materials

► Steel, stainless steel, tool steel, hardened steel, Hardox

► Non-ferrous and light metals

► Copper, brass, bronze, aluminum, titanium

► Plastics, acrylic and plexiglass, hard glass fabric, carbon, HGW, insulation materials, foam, rubber

► Glass, ceramic materials, oxide ceramics, silicon carbide

► Natural stone, artificial stone, marble, tiles, borders, mosaics, ornaments, rosons

► Composite materials, dibond, plywood, multiplex, laminates

Request regarding Waterjet Cutting:

About us

Our company

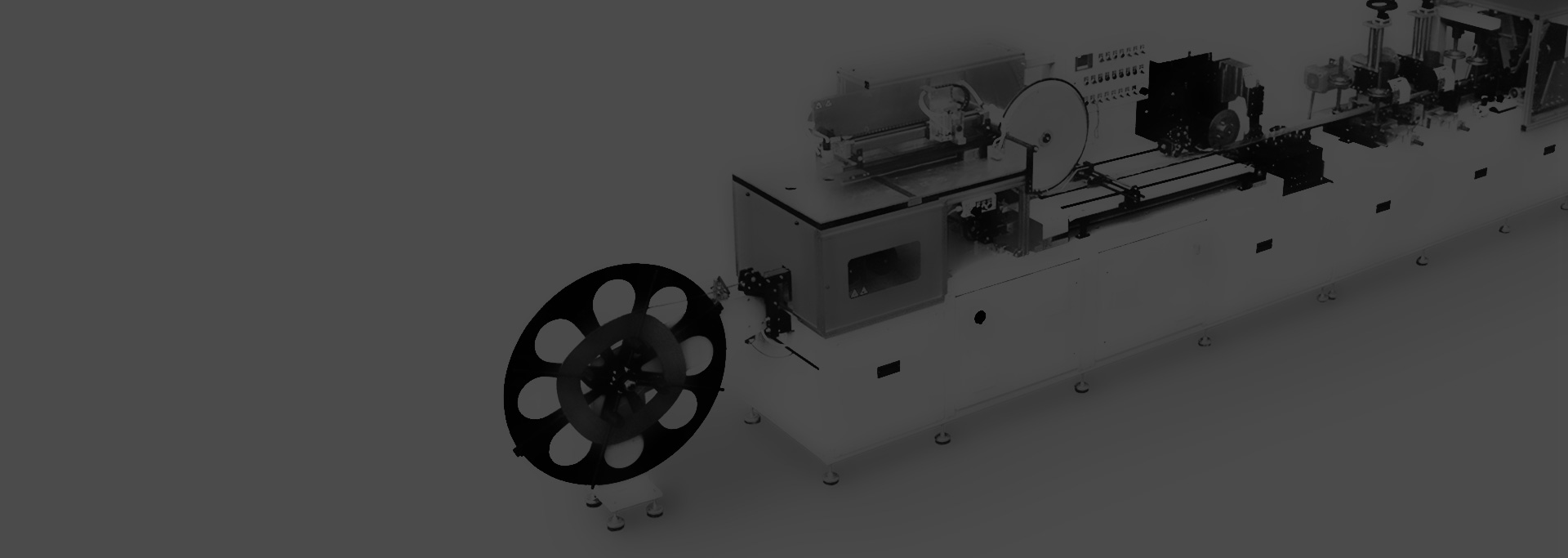

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com