Hopper Feeder

The operator inserts the wooden boards pre-planed to the finished height into the stacking magazine. The feeder pushes the board by a CNC axis exactly into the middle of the clamp. To increase capacity, the feeder can be switched to batch processing, so you can get two or more boards loaded into the clamping station all at once and processed here by the milling cutters.

Rotating Table and Clamping

The highlight of this machine is its turntable, which forms the lower part of the workpiece clamping. From above, an adjustable pressure cylinder holds the workpiece in position. With the turntable, the milling of different contours of the highest quality is guaranteed, because the milling cutters never work against the wood fiber.

Electronic central lubrication system

The carriages of the CNC axes and all other machine parts to be lubricated are continuously supplied with grease via the electronically controlled central lubrication system and hereby protected against the ingress of wood dust. This guarantees an absolutely quiet and low-wear run. The central lubrication system is programmed and monitored by a small digital display directly on the pump.

Milling Devices

Two powerful drives bring the cutters to about 9,000 revolutions. On request, higher speeds are possible.

The two milling cutters shape the individual contour of the workpiece by moving it in and out of the turntable. Depending on which profile or radius the outer edge should have, the cutters are manufactured with the appropriately profiled knives. In most cases, it is possible to use cutters with interchangeable plates, so that the tool costs can be significantly reduced. It's possible to create two different profiles in one operation by using both cutters with different knives.In addition to working with both tools, the use of only one tool is possible.

The milling devices are easily adjustable in height, so that a certain tolerance range is covered. The adjustable tool compensation via the control system guarantees a consistently good milling pattern even after sharpening the cutters.

CNC Controls

The 4-axis CNC control system used here was specially developed by WOMAtec for this application. A total of four servo drives are controlled: feeder, turntable and two tool carriers. The machine speed is variable, whereby individual units can be readjusted. In addition, the speed of the milling motors can be controlled continuously via frequency converters.

The milling contour is entered via teach-in or conveniently by CAD file, which is converted into machine-readable production data using the WOMAtec Converter. Various operating modes make it easier to set up the machine for a new workpiece pattern. Thanks to the CNC control, it is no longer necessary to change templates.

Based on Beckhoff components, the WOMAtec control guarantees maximum ease of use, a long service life and easy spare parts availability.

Ejection

The finished shaped workpiece is pushed back into a slide by inserting the new board from into clamping. Here, e.g. a conveyor belt for removal are tied.

Dust Exhaustion

Depending on the milling pattern, it can lead to high chip removal, which should absolutely be removed from the machine interior. For this purpose, at the critical points sufficiently large openings are present, the tubes are merged on the back of the machine for connection to an external stationary or central exhaust. In addition, the housing protects against excessive dust and noise in operator's working area.

Machine Frame

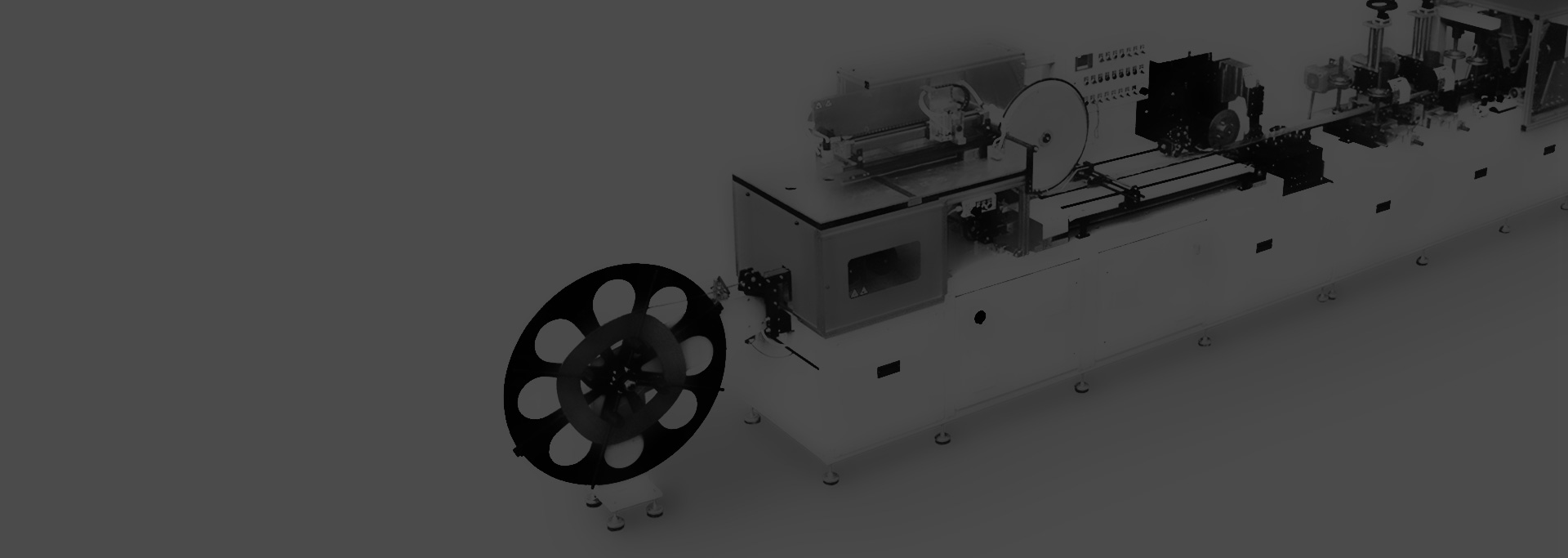

Thanks to its compact design, the entire system only needs an area of about 2.00 x 2.00 meters. The base plate on which the two milling units are running is mounted on the stable welded frame. The drive of the turntable sits in the lower part of the machine. Powder-coated cover panels protect the interior from dirt and ensure a clean look.

Safety Housing

The complete upper part of the machine is covered by a large protective hood whose doors are secured with safety switches. These are integrated in the safety chain of the machine control.

ROTARY 2.0 CNC

The WOMAtec "ROTARY 2.0 CNC" automatic copying shaper has been designed for the efficient production of contour shaping parts such as brush and broom blocks, handles or breakfast boards. From design to programming to production, WOMAtec realizes everything in-house. Thanks to the sophisticated machine concept and the solid and high-quality construction, you get a machine that is characterized by:

- an excellent milling image

- easy operation and maintenance

- reliability and longevity

- high productivity and flexibility

- low noise and dust emission

- high proportion of standard parts and thus

- easy access to wear and spare parts

- Workpiece. Maximum length 400 mm.

- Capacity. About 10 to 15 seconds per milling process - depending on the size and shape of the workpiece.

- Changeover time. Depending on the workpiece, 15 to 45 minutes with adjustment of the magazine, replacement of the clamping supports and milling cutters.

- PDF file

Request regarding ROTARY 2.0 CNC:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com