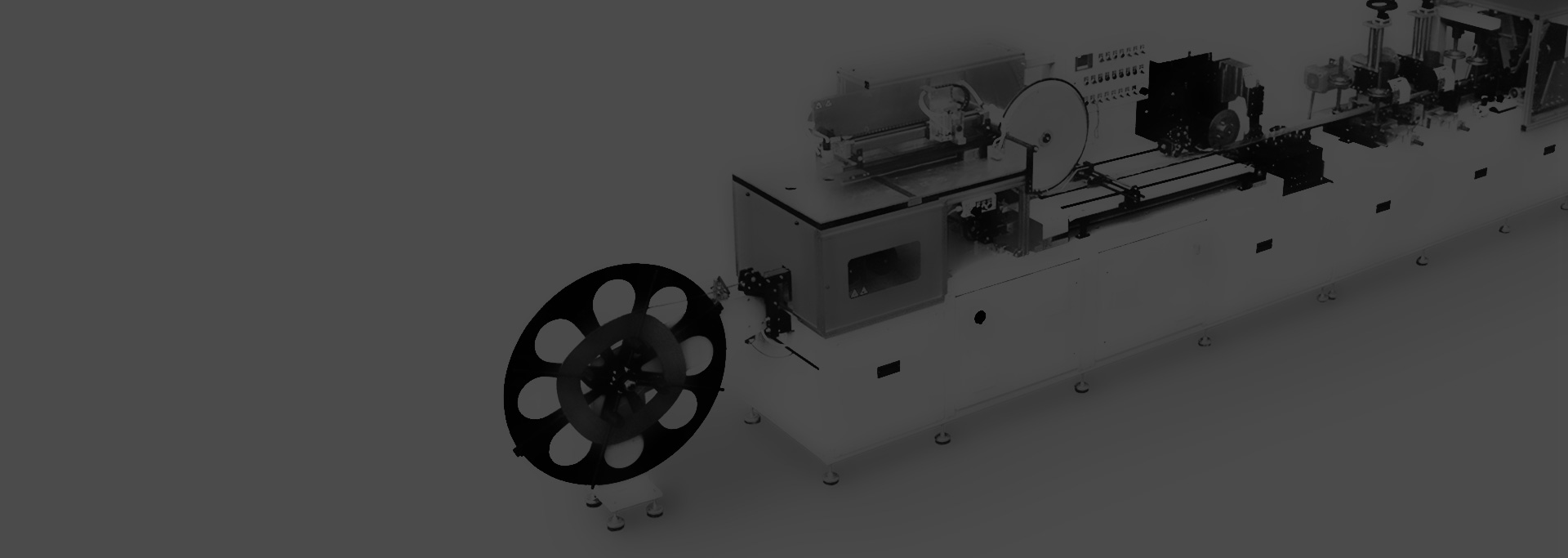

Band Coiler

Depending on the requirements, the flat band of steel, stainless steel or aluminum comes into the roll forming from one or more coils.

Drive & Controls

Powerful geared motors or latest servo drives. Stepless speed control.

With the lowest possible electronic effort, we achieve maximum ease of use. Simple operation, longer life and low susceptibility to failure are the advantages of this control concept.

Profiling

Centered, the steel band enters the forming station, where pairs of driven rollers form the required profile exactly.

Machine Frame

Steel frame. Covers. Safety guards. Control cabinets.

Everything on board - the solid welded steel frame hides drives and control cabinets. Powder-coated cover panels protect the interior from dirt and ensure a clean look. Enclosures at safety-relevant points are secured with limit switches.

Transfer

The finished shaped band is provided exactly guided for further processing. For example, overmolding with a rubber or plastic coating.

Roll Forming Devices

Do you need a roll forming device? WOMAtec develops and builds machines for special applications, in series or as a prototype. From planning through CAD design to production, we are the right partner for you.

At the planning of individual solutions we try for:

- easy operation and maintenance

- solid construction

- reliability and longevity

- high proportion of standard parts and thus

- easy access to wear and spare parts

We accompany you from the first idea to the production stage.

Benefit from our experience with machines of all kinds in the fields of wood processing and brush production.

- Design. You want to make a special product, but there is no machine on the market for it? Together we collect ideas, make suggestions for solutions and designs.

- Construction. If the idea has grown in your mind, it has to be on paper - or better, in CAD. Our design department translates the designs into production-ready drawings.

- Manufacture. Most of the production parts are produced directly in our fully equipped workshop. Special components and standard parts come from partners in the region. With trial runs under production conditions, we ensure that the machine will fulfill its purpose permanently and reliably after delivery.

Request regarding Roll Forming Devices:

About us

Our company

WOMAtec Maschinenbau GmbH was created in 2015 from the used machine trade WOMA. Company founder Daniel Koehler has been trading since 2008 with used machines for woodworking and the brush industry. At first only machines are bought and sold again. Focused on the international market right from the start, the company is rapidly becoming an established service provider in the field of machine overhaul, repair and spare parts. It was only a small step to new machine construction.

Fascinated by the solid functionality of old machines, Daniel Koehler picks up proven technologies at WOMAtec Maschinenbau GmbH and develops them further for modern production operations...

References

Worldwide in Use.

WOMAtec machines come in use not only in Germany and Europe. Thanks to their ease of use, a high proportion of standard components and the largely avoidance of fault-prone electronic components, WOMAtec systems meanwhile operate in countries such as India, Indonesia, Canada, South America and the USA.

References White Box

"You should be proud...

...of the machines you are building. This machine is world class. No one in the world makes a better machine. We have been in the brush industry for 40 years, and have never seen a machine as nice as this."

Brian M. Chaltry & Bob Duffrin, CMB Mfg LLC, Michigan / USA

- WOMAtec Strip Brush Machine SSB 1.0 -

Contact

WOMAtec Maschinenbau GmbH

- Am langen Streif 8

36433 Bad Salzungen - Phone +49 (0)3695 858450-0

Fax +49 (0)3695 858450-9 - info@WOMAtec.com